China +1 success in works? How Indian electronics manufacturers are matching China’s cost advantage

[ad_1]

Atul Lall, Managing Director of Dixon Technologies, stated that discussions with global customers, particularly laptop and tablet brands, indicate that they have nearly reached China’s manufacturing cost.Pardeep Jain, Chairman of Karbonn, emphasized that the key factor enabling cost parity with China has been the Indian government’s production-linked incentive (PLI) scheme.

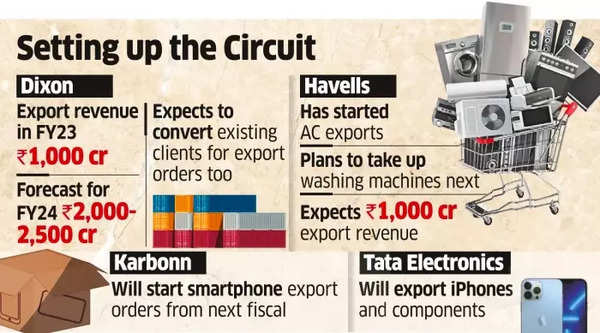

Dixon Technologies is expanding its lighting exports to new customers in Germany and the UK and is gearing up to export mobile phones for anchor customers, including Motorola and Nokia. Additionally, the company will commence exporting components such as inverter controller boards for air conditioners, currently supplied to Daikin within the domestic market.

China + 1: Electronics exports

Dixon anticipates export revenue of Rs 2,000-2,500 crore for the current fiscal year, a significant increase from Rs 1,000 crore in FY23, with continued exponential growth in the future.

Lall highlighted the need to match China’s manufacturing costs for success, especially for products like laptops and tablets that do not have import duties. He explained that they achieved this cost parity by studying the operations and cost management of large Chinese contract manufacturers and benchmarking their operations accordingly. Further investments in automation are planned to maintain this cost parity across products.

While global brands like Apple have exported products from India through plants set up by their global manufacturing partners, companies like Samsung and LG have established their own factories for exports. Notably, it is the first time that global brands, including Chinese-owned ones like Xiaomi, are exploring exports from Indian contract manufacturers.

Tata Electronics, the contract manufacturing arm of the Tata group, is set to make a significant move into iPhone production by acquiring Wistron Corp’s India operations, known for assembling iPhones. This marks a milestone, making Tata Electronics the first Indian entity to manufacture iPhones for both the domestic and global markets.

Explained: How India has scripted a smartphone exports success story

While Apple has chosen not to comment on this development, inquiries to Tata remained unanswered as of the publication time.

Karbonn’s Jain emphasizes the importance of building a robust component manufacturing base in India, considering the growing interest of global brands in the country for manufacturing as part of their China+1 strategy.

Havells India has also entered the contract manufacturing sector, focusing on air conditioners for global brands in markets like West Asia and the US. The company has plans to expand into manufacturing washing machines and aims to achieve export revenue of Rs 1,000 crore in the coming years.

#China #success #works #Indian #electronics #manufacturers #matching #Chinas #cost #advantage